About MOONS

MOONS' is one of the largest integrated manufacturers of motion control products within China, using internationally proven scientific

management tools along with the pursuit for professional applied technologies.

MOONS' continuously develops products that conserve energy, are more convenient and efficient in utilization and application, bringing

assurance to the customers and creating values for them.

MOONS' products range from factory automation components to the intelligent LED drivers, from the intelligent management system of large

industrial equipment to the control actuator in automotive and telecommunication devices.

- MOONS' was established in February 1994.

- Headquartered in Shanghai, China.

- Subsidiaries located in North America, Europe ,East Asia and Southeast Asia.

As an integrated manufacturer of high-quality motion control products, our

purposes are

- To optimize the motor design, engineering and manufacturing

- To enhance our process and quality control

- To provide more efficient, energy-saving motion control products and solutions

for customers around the world

As an ambitious and enterprising company, MOONS' goal is to never stop

improving our processes and increasing our efficiency;

- We study scientifically proven management ideas

- We pursue advanced technology and high-level managerial talent

- We regularly review our existing management systems and our operational methods

- We are continually improving our management process and organizational systems

We believe these endeavors enable us to maintain strong presence in a competitive

market.

Quality

MOONS' provides professional workmanship and support services including design and application engineering, rapid product prototyping and delivery,

along with ISO certified quality through TUV, and dedication to 100% customer satisfaction. Our engineers and designers utilize the latest

equipment and technology to design products for reliability, consistency, and outstanding quality that will meet and/or exceed our customers'

requirements. Our factories are certificated according to ISO 9001:2000 / ISO 14001:2004 and BS OHSAS 18001:2007.

Products

Highlight: MS08HY (New Product)

20mm/NEMA8 Bipolar Hybrid 1,8° Stepper (0,028-0,058 Nm)

2 phases 1.8° hybrid stepper motor is the most popular in market and has the most extensive product coverage, as a result of a series of optimizations and improvements,

its performance and value has been greatly improve

Properties

- Phases 2

- Steps / Revolution 200

- Step Accuracy ±5%

- Shaft Load (20,000 Hours at 1000 RPM)

- Axial 6 N (1.3 Lbs.) Push

- Axial 25 N (5.6 Lbs.) Pull

- Radial 18 N (4 Lbs.) At end of shaft

- IP Rating 40

- Approvals RoHS

- Operating Temp. -20°C to +50°C

- Insulation Class B, 130°C

- Insulation Resistance 100 MegOhms

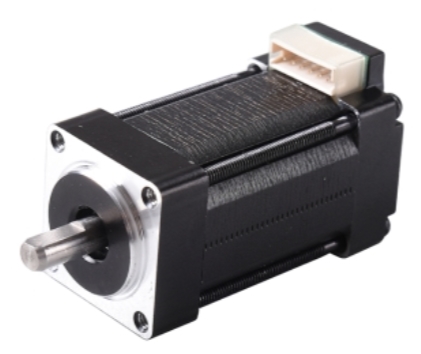

Highlight: Ecapsulated Stepping Motors

New Encapsulation Technology From MOONS' Offers Many Advantages

Low Temperature Rise

The winding resistance of these new motors is nearly 30% lower than other motors with the same thickness and output-torque. In addition, the new

encapsulation technology increases the heat-conducting property of these motors. The lower winding resistance and improved thermal conductivity

combine to drastically lower the temperature of these motors to less than 80% of standard motors.

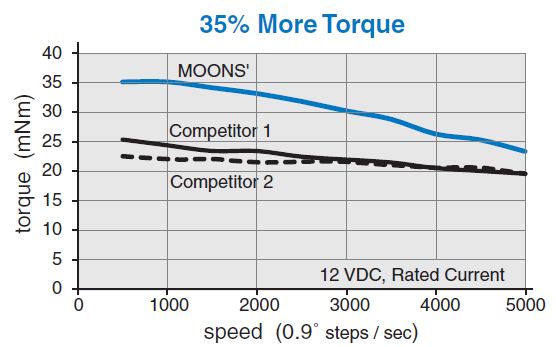

35% More Torque

Lower resistance coils allows these encapsulated motors to handle more power. With the same temperature rise the new motors can produce 35% more

torque while dissipating the same amount of heat.

Quieter & Smoother

New materials and improved manufacturing processes, means these motors have a higher precision, more stable design. This controls vibration and reduces

noise. It also makes the motor run smoothly.

More Load & Longer Life

MOONS’ encapsulated stepping motors use large bearings that can handle large axial and radial loads, and ensure long life.

14HK Series: Size 14, 0,9°

14HK Series: Size 14, 0,9°

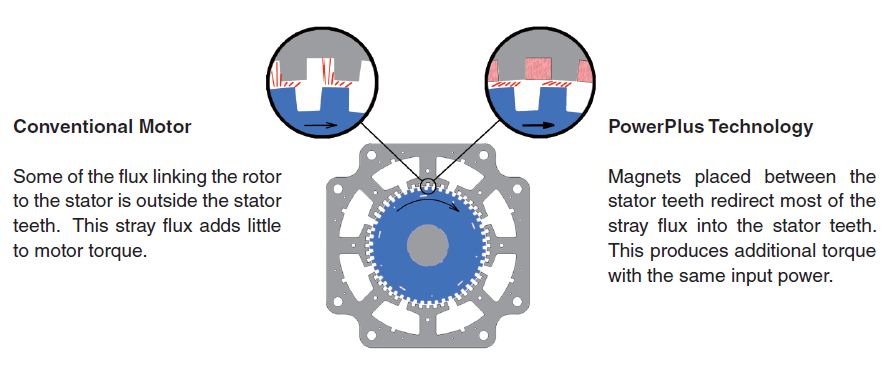

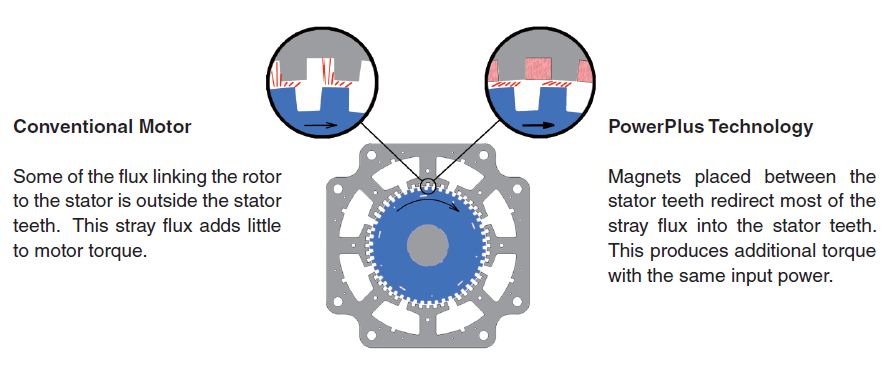

Highlight: PowerPlus Technology

NEMA Size 23 & 34 (56 & 86mm) motors are available with MOONS’ PowerPlus technology.

This technology provides 25% to 40% more torque across the entire speed range of the motor.

The increased torque is a result of higher motor efficiency, and is available without increasing the drive voltage or current.

Typical Applications

Machine Upgrades

Changing existing machines to PowerPlus motors can be a quick path to new models with higher performance.

Because the motor, drive and mechanical parts remain the same benefits include:

- Faster new product introduction

- Reduced engineering costs

- Easy production phase in

- Reduced spare parts inventory

Correct stalling problems with existing machines

Problems with occasional machine stalling are often due to unexpected field conditions that require

more torque. These include: low temperature, dirt, and customers using machines in unexpected ways.

UsingPowerPlus motors can be a quick effective solution.

Overcome drive or power supply limitations in new designs

Often a higher current drive or higher voltage power supply can provide needed extra torque. However,

in many designs the drive current cannot be increased without switching to a larger, more expensive

drive. Increasing drive voltage can be impractical, expensive, or may not be allowed for safety reasons.

In these cases using PowerPlus motors can be especially useful.

Cost: about 1,5x to 2x the price of a standard motor

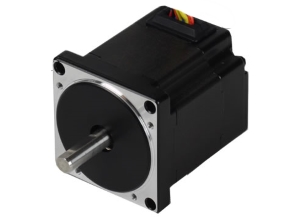

1,8° Hybrid Stepper

1,8° Hybrid Stepper

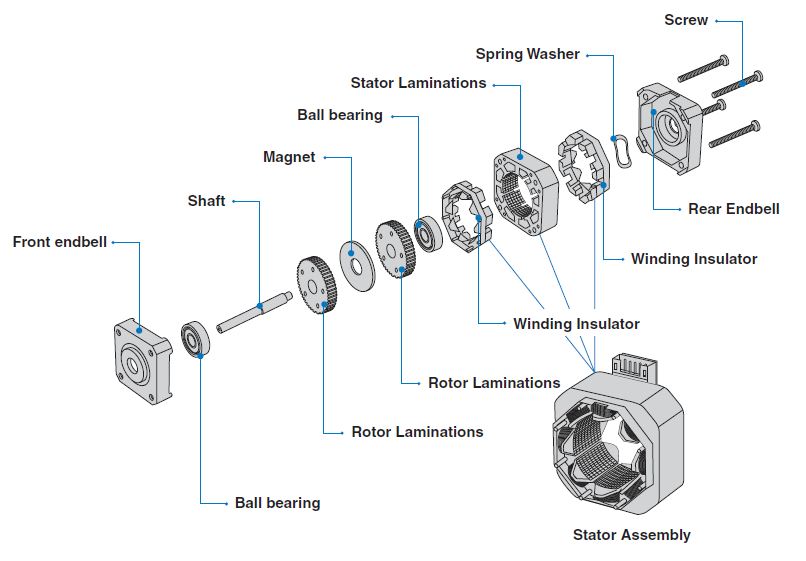

Hybrid Stepper Motors

MOONS Hybrid Stepper Motors Catalog (PDF)

MOONS Hybrid Stepper Motors Catalog (PDF)

1,8° Hybrid Stepper

2 phases 1.8° hybrid stepper motor is the most popular in market and has the most extensive product coverage, as a result of a series of optimizations

and improvements, its performance and value has been greatly improved.

| Motor |

Series |

NEMA |

Flange Size |

Holding Torque |

Links |

|

8HY |

8 |

20 mm |

0,018 - 0,040 Nm |

|

|

MS08HY |

8 |

29.5 mm

39.5 mm

46.5 mm |

0,028 - 0,058 Nm |

|

|

MS11HS |

11 |

28 mm |

0,09-0,17 Nm |

|

|

MS14HS |

14 |

35 mm |

0,1-0,4 Nm |

|

|

MS16HS |

16 |

39 mm |

0,27-1,5 Nm |

|

|

MS17HD |

17 |

42 mm |

0,2-0,83 Nm |

|

|

ML23HS |

23 |

57mm |

0,82-3,2 Nm |

|

|

MS24HS |

24 |

60mm |

1,23-3,3 Nm |

|

|

ML34HD |

34 |

86mm |

3,7-11,9 Nm |

|

|

ML42HS |

42 |

110mm |

12,1-32 Nm |

|

1,8° Hybrid Stepper

1,8° Hybrid Stepper

1,8° PowerPlus Hybrid Stepper

2 phases 1.8° hybrid stepper motor is the most popular in market and has the most extensive product coverage, as a result of a series of optimizations

and improvements, its performance and value has been greatly improved.

MOONS’ PowerPlus technology provides 25% to 40% more torque across the entire speed range of the motor. The increased torque is a result of higher

motor efficiency, and is available without increasing the drive voltage or current.

| Motor |

Series |

NEMA |

Flange Size |

Holding Torque |

Links |

|

PL23HS |

23 |

57mm |

2,3-3,4 Nm |

|

|

PL34HD |

34 |

86mm |

4,7-15 Nm |

|

1,8° Hybrid PowerPlus Stepper

1,8° Hybrid PowerPlus Stepper

Link: PowerPlus Technology

Content

0,9° Hybrid Stepper

High Precision Hybrid Stepper Motors. It can make a very accurate motion of small incremental step angle with 0.9°, when cooperating with the

differential stepping driver, it achieves ultra precise subdivision step angle.

| Motor |

Series |

NEMA |

Flange Size |

Holding Torque |

Links |

|

14HK |

14 |

35 mm |

0,044-0,12 Nm |

|

|

MS14HA |

14 |

35 mm |

0,1-0,32 Nm |

|

|

MS17HA |

17 |

42 mm |

0,25-0,55 Nm |

|

|

ML23HA |

23 |

57mm |

0,59-2,4 Nm |

|

0,9° Hybrid Stepper

0,9° Hybrid Stepper

Content

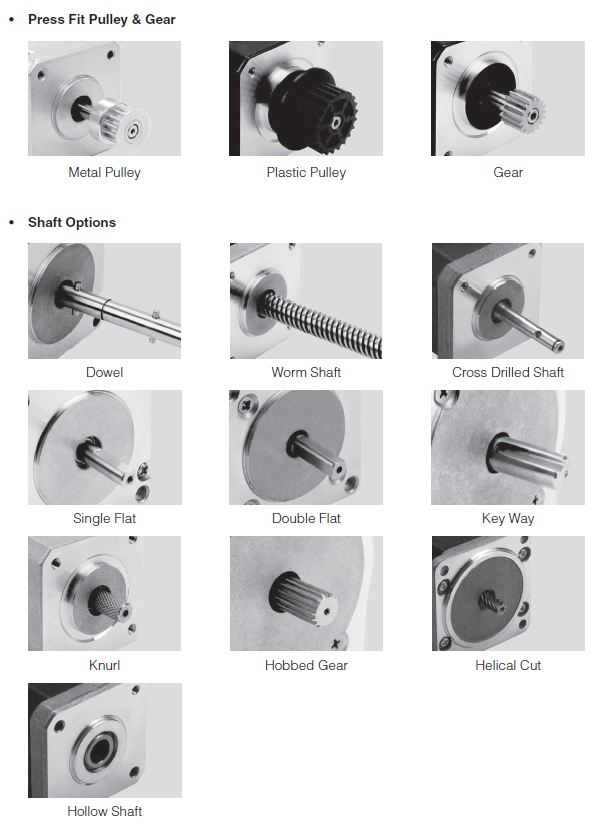

Shaft Options

Content

PM Stepper

Compared to Hybrid Stepper Motors, PM Stepper Motors have a simpler design.

The step angle is larger resulting in a cost effective motor with reduced physical dimensions.

The max. speed is higher with bigger step angle.

| Motor |

Series |

Size

[mm] |

20 Steps

18° |

24Steps

15° |

48 Steps

7,5° |

96Steps

3,75° |

Links |

|

20PM |

20 |

20PM020S

20PM020L |

- |

- |

- |

|

|

25PM |

25 |

- |

25PM024S

25PM024L |

25PM048S

25PM048L |

- |

|

|

35PM |

35 |

- |

35PM024S

35PM024L |

35PM048S

35PM048L |

- |

|

|

45PM |

45 |

- |

- |

42PM048S

42PM048L |

42PM096S

42PM096L |

|

PM Stepper

PM Stepper

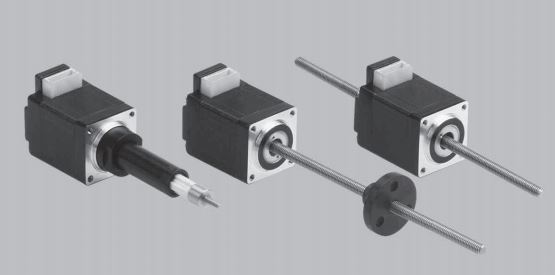

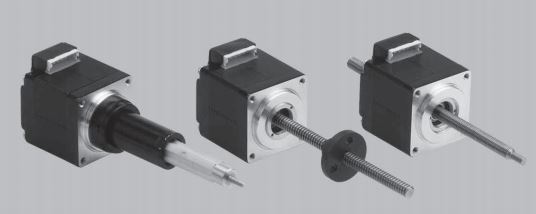

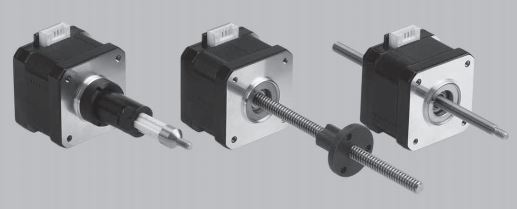

Linear Stepper Actuators

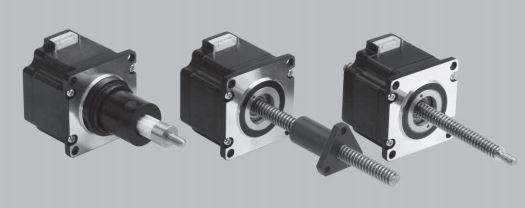

There are tree basic types of Linear Stepper Actuators:

Captive: internal screw, lock again rotation

Non-Captive: internal screw, no lock against rotation

External: external screw

Linear Stepper Actuators

Linear Stepper Actuators

Linear Hybrid Stepper Actuators

MOONS’ has combined years of hybrid step motor experience, with quality leadscrews and nuts, to create the L Series linear actuators. The L Series

linear actuators provide more force, high precision, and options to fit the application needs of machine designers.

- 3 styles of linear actuators

- Five frame Sizes: 8, 11, 14, 17, 23

- Multiple motor lengths and PowerPlus size 23 provide a total of 12 different motor sizes

- Each motor size has 3-8 different standard lead screws

- Each motor size has a selection of standard windings

In addition… MOONS’makes may custom actuators, so you can get exactly what you need.

| Motor |

Size

NEMA |

Size

[mm] |

External

Spindle |

Captive |

Non-

Captive |

Links |

|

8 |

20 |

LE8HY |

LC8HY |

LN8HY |

|

|

11 |

28 |

LE11HS |

LC11HS |

LN11HS |

|

|

14 |

35 |

LE14HS |

LC14HS |

LN14HS |

|

|

17 |

42 |

LE17HD |

LC17HD |

LN17HD |

|

|

23 |

56 |

LE23HS |

LC23HS |

LN23HS |

|

The combination of actuator styles, sizes, lead-screws and windings, gives the freedom to use motors of different form factors to exactly fit in the

application. And, it provides the most performance with any drive and power supply. The L Series includes several advanced patent pending technologies

to provide the best efficiency and long life, in a compact package.

L Series linear actuators are offered with a variety of lead-screws, that are designated by their lead. Lead is the distance the nut travels when the

lead-screw turns one revolution. For a given motor, larger leads will move the nut faster, but with less force.

To determine the linear movement per step divide the screw lead by the motor steps / revolution. For example: Lead designation E062 has a lead of 1.588

mm (.0625”). With a 1.8 degree step motor the movement per step is 1.5875 / 200 = 0.00794 mm / step (.062 / 200 = 0.0003125 inch / step). Note: the E in

the E062 designation indicates this is based on inches, and the mm values have been rounded.

Linear Actuator Permanent Magnet (PM) Stepper Motors

| Motor |

Size

[mm] |

Captive |

Non-

Captive |

Links |

|

20 |

LC20P |

LN20P |

|

|

25 |

LC25P |

LN25P |

|

|

35 |

LC35P |

LN35P |

|

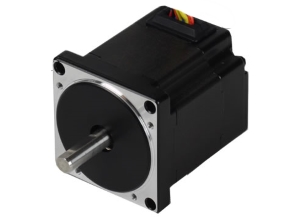

BLDC Motors

MOONS' BLDC Motors: small volume with great output power, lower temperature rise,lower noise ,lower vibration long service life,lower maintenance cost

lower detent torque.

| Motor |

Series |

Flange Size |

Power |

Torque |

Links |

|

42BLD |

42mm |

30W

60W

90W |

72-215 mNm |

|

|

57BLD |

57mm |

60W

120W

180W |

145-430 mNm |

|

|

80BLD |

80mm |

100W

200W

300W |

240-720 mNm |

|

BLDC Motors

BLDC Motors

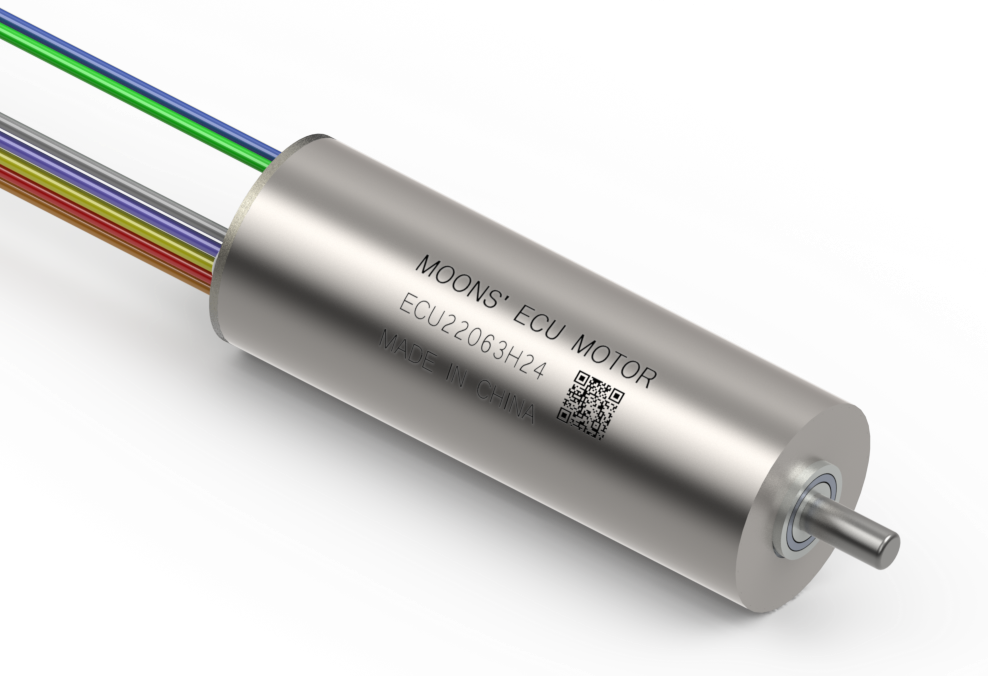

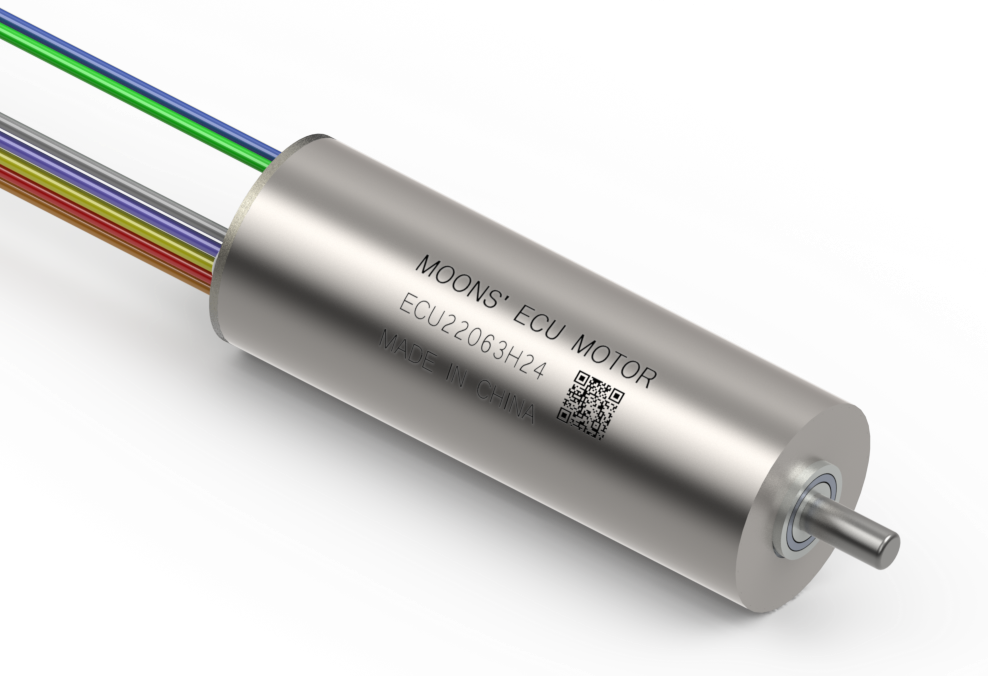

Slotless BLDC Motors

MOONS’ high performance slotless BLDC motor use independent patented ironless winding, this special design can bring high speed, high torque and

low noise. Because of no cogging and compact structure, we can get smoother running at high or low speed, more accurate control, higher efficiency and higher power density.

- Ironless Winding

- Small Size

- High Torque

- High Speed (50.000-60.000 rpm)

| Motor |

Series |

Flange Size |

Power |

Torque |

Links |

|

ECU13026 |

13mm |

4,5/9W |

2,31-2,45 mNm |

|

|

ECU13038 |

13mm |

10/20W |

5,13-5,55 mNm |

|

|

ECU22063 |

22mm |

120/180W

|

45,9-47,5 mNm |

|

Slotless BLDC Motors

Slotless BLDC Motors

Planetary Gearheads for Slotless BLDC Motors

| Motor |

Series |

Flange Size |

for

Motor Series |

Models |

Links |

|

PG13C |

13mm |

ECU13026

ECU13038 |

2 stages: 16:1, 19:1

3 stages: 66:1, 77:1, 90:1

4 stages: 271:1, 315:1, 366:1, 425:1 |

|

|

PG22C |

13mm |

ECU22063

|

1 stage: 4:1, 5:1

2 stages: 16:1, 19:1, 22:1

3 stages: 64:1, 76:1, 90:1, 107:1

4 stages: 256:1, 304:1, 361:1, 428:1,

509:1 |

|