|

|

Homepage |

Company Profile |

Selector Guides |

Datasheets |

| Picture | Features | Links |

|---|---|---|

|

|

Broschure Datasheets (Coming Soon) |

| Picture | Features | Links |

|---|---|---|

|

|

Broschure Datasheets (Coming Soon) |

| Pictures | Features | Links |

|---|---|---|

|

|

Datasheets (Coming Soon) |

| Pictures | Features | Links |

|---|---|---|

|

|

Broschure Datasheets (Coming Soon) |

| Product-Types | Pictures | Features | Links |

|---|---|---|---|

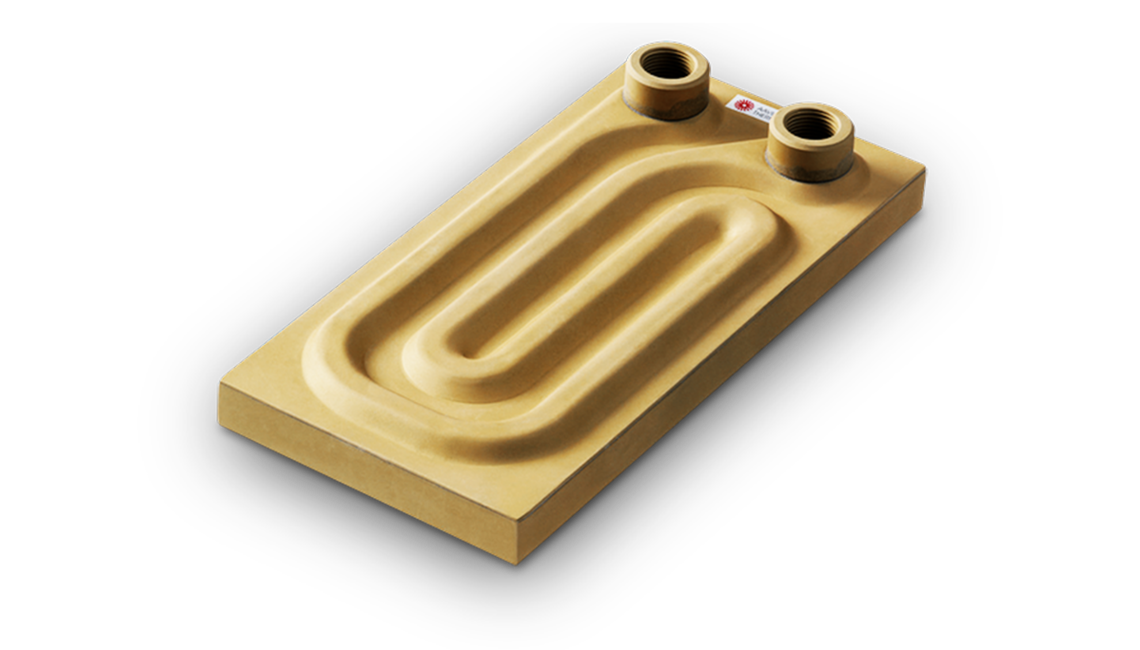

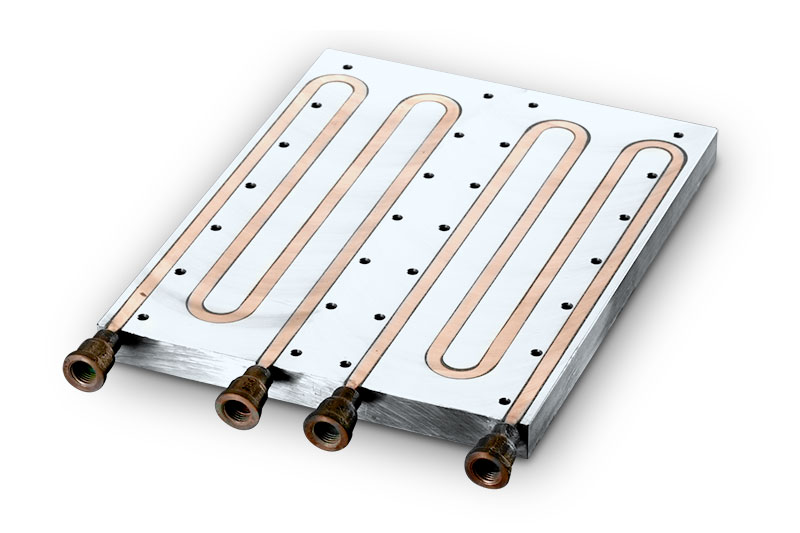

| Brazed Liquid Heat Sinks |  |

|

Broschure Datasheets (Coming Soon) |

| Super Plates |  |

|

| Picture | Features | Links |

|---|---|---|

|

|

Broschure Datasheets (Coming Soon) |

| Product Type | Pictures | Description | Specifications | Links |

|---|---|---|---|---|

| DC/AC Flat Fans |  |

|

|

Broschure Datasheets (Coming Soon) |

| DC Fan Blowers |  |

|

|

|

| New: "Golf" DC Fan |  |

|

|

| Products | Pictures | Features | Links |

|---|---|---|---|

| Rotary Knobs |  |

|

Broschure Datasheets (Coming Soon) |

| Scrubber Knobs |  |

|

|

| Customised Knobs and Plastic Housings |  |

|

|

| Accessories |  |

|

| Picture | Description | Useful Products |

|---|---|---|

|

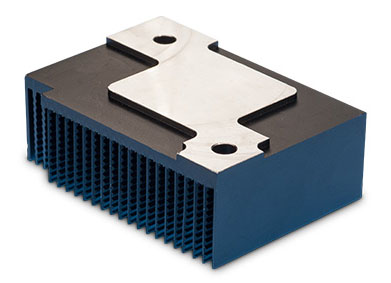

Medical technical devices can save lives. The quality standards for such devices are therefore extremely high. All components built into a medical technical device, including of course heat sinks and fans, must meet stringent quality criteria as regards reliability and durability. High-performance heat sinks and efficient fans dissipate the heat produced by the electronic components installed in the medical technical device, ensuring that it works properly all the time across its service life. Many medical technical devices are fitted with liquid heat sinks, as they offer optimum cooling performance and take up only little space. |

| Picture | Description | Useful Products |

|---|---|---|

|

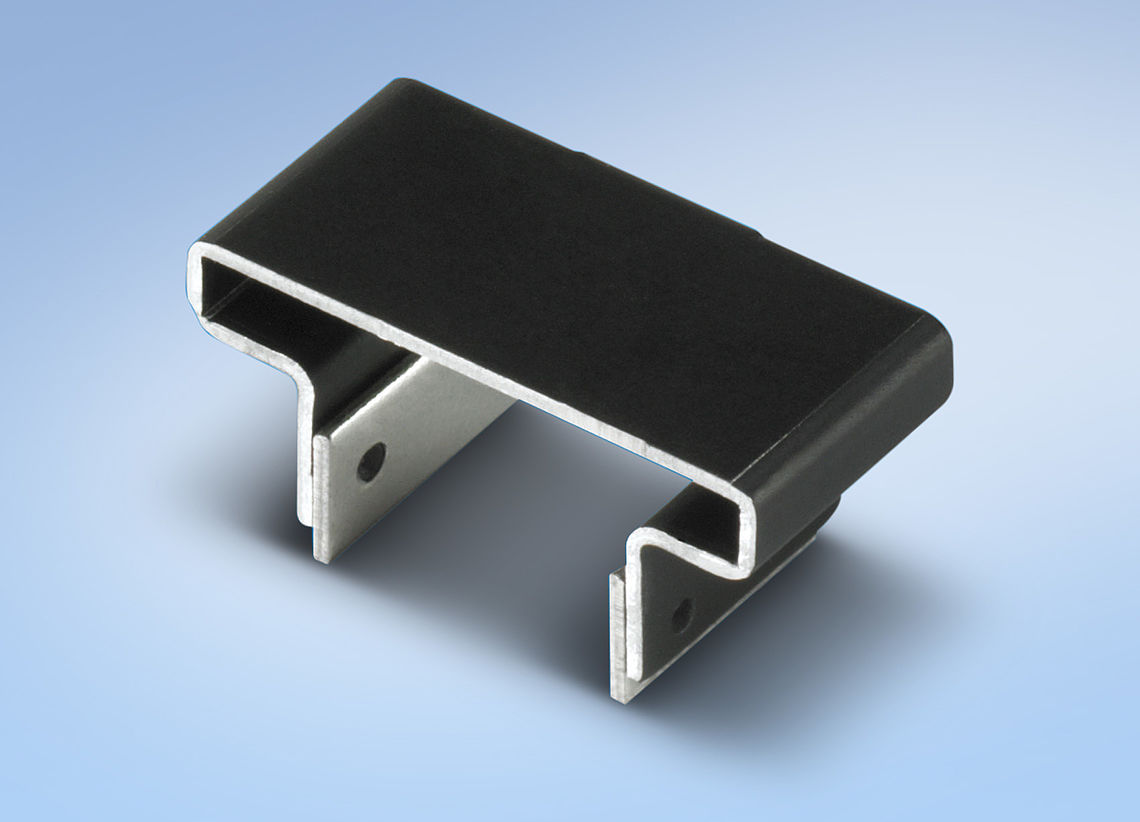

Washing machines and refrigerators, TVs and mp3 players – they all feature electronic components. Without them, no laundry can be washed, the milk would get sour, there would be no picture on the screen and no music from the headphones. Electronic components in household appliances and home electronics have made these devices more powerful and at the same time smaller than ever. Such packed power comes at a price: inside the devices, a lot of heat is produced that needs to be dissipated as quickly and as efficiently as possible. Otherwise, the devices would quickly break down. To prevent this, they are equipped with clip-on or profile heat sinks, or special heat sinks for SMD components and printed circuit boards. |

| Picture | Description | Useful Products |

|---|---|---|

|

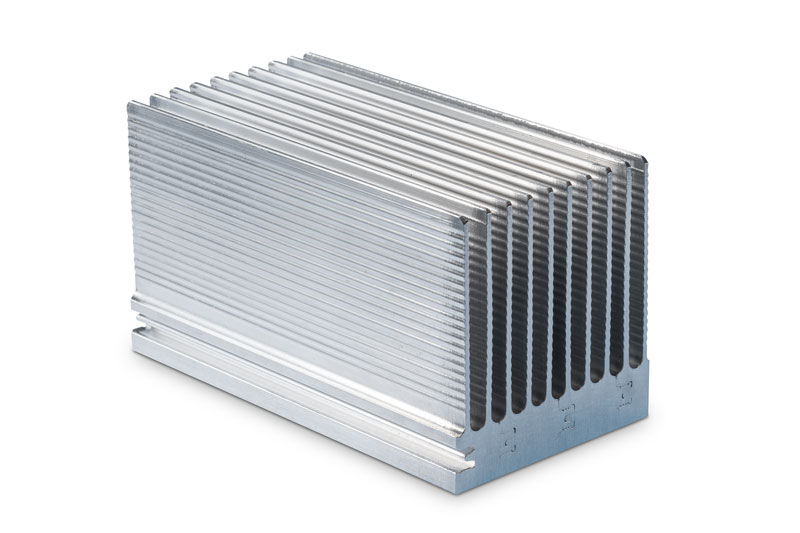

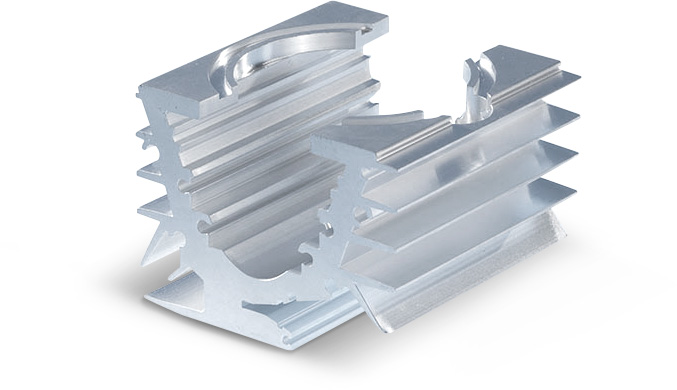

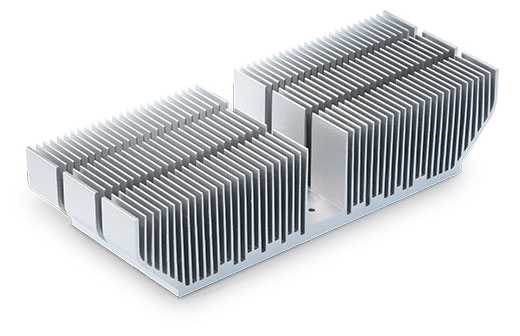

Technical equipment used in public transport systems such as trains must meet particularly high standards as regards safety, reliability and durability. At the same time, the units should not take up too much space in railway carriages. The technical components must thus be small yet powerful and of excellent quality. This also applies to the electronic parts used in trains. High-performance parts installed in small spaces result in high power loss per cubic metre. This heat must be quickly dissipated in order to protect the electronics against damage. For this purpose, train electronics are normally equipped with high-performance liquid heat sinks. Some of these measure up to 2 m and weight around 200 kg. Such large heat sinks are for example found on inverters. |

| Picture | Description | Useful Products |

|---|---|---|

|

High-performance LEDs are energy-efficient and safe. Their service life and efficiency is significantly higher than that of conventional incandescent bulbs. However, LEDs still produce significant amounts of heat. This heat is transferred by the depletion layer through the metal connections to the PCB and dissipates into the environment. The temperature of the depletion layer also affects the dominating wavelengths and the brightness of the LED, and thus the colour of the emitted light. As the temperature increases, the brightness of the luminaire is gradually reduced while there is a marked colour change. To control the temperature of high-performance LEDs, optimised application-specific LED heat sinks are a must. They do not only prolong the service life of the luminaire but also ensure uniform brightness and light colour. |

| Picture | Description | Useful Products |

|---|---|---|

|

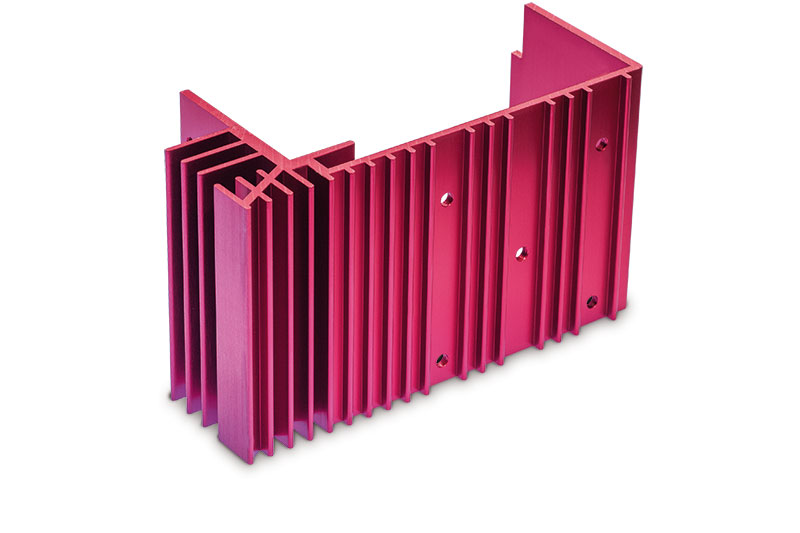

Modern renewable energy plants feature a wide range of electronic assemblies, such as control units for the alignment of the rotor blades and yaw control devices in wind turbines, or inverters in photovoltaic plants. When the temperature inside these devices increase, their performance drops, reducing the efficiency of the entire plant. For reliable and efficient power generation, the electronic assemblies need to be constantly cooled. This is done through high-performance heat sinks, or cooling housings, which is the preferred option for inverters. As renewable power plants are often exposed to extreme weather conditions and are generally hard to access, their cooling equipment must meet particularly stringent requirements: They must be corrosion-proof and durable, and maintenance must be reduced to a minimum. |