|

|

Homepage |

Datasheets |

Presentations |

Flyers |

Catalog Selector Guide |

Location: Cambridge, UK

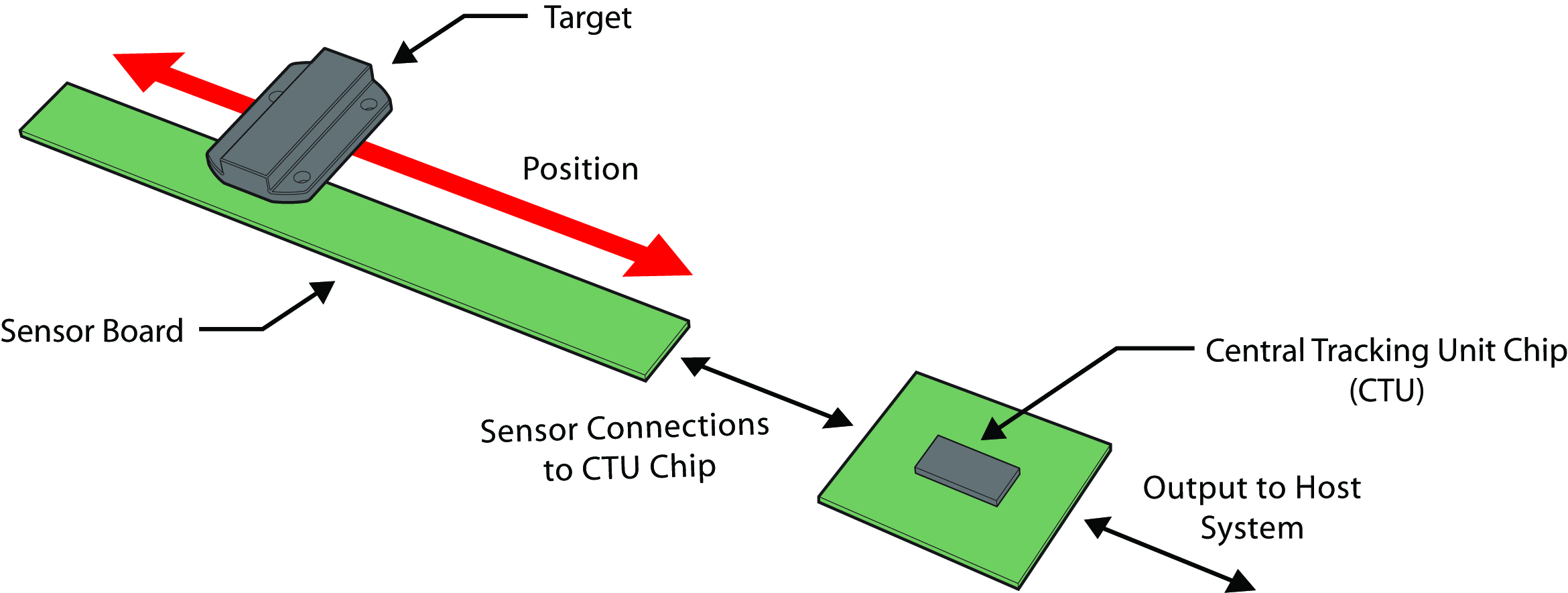

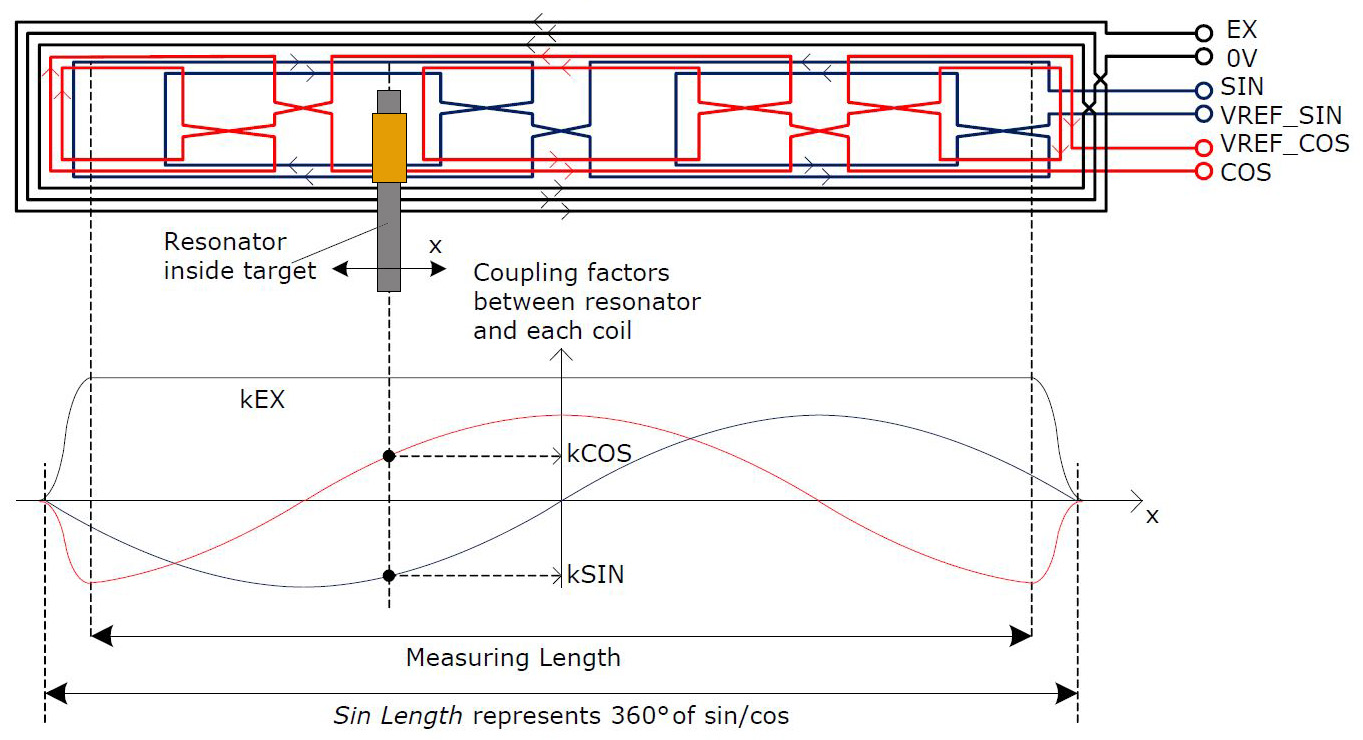

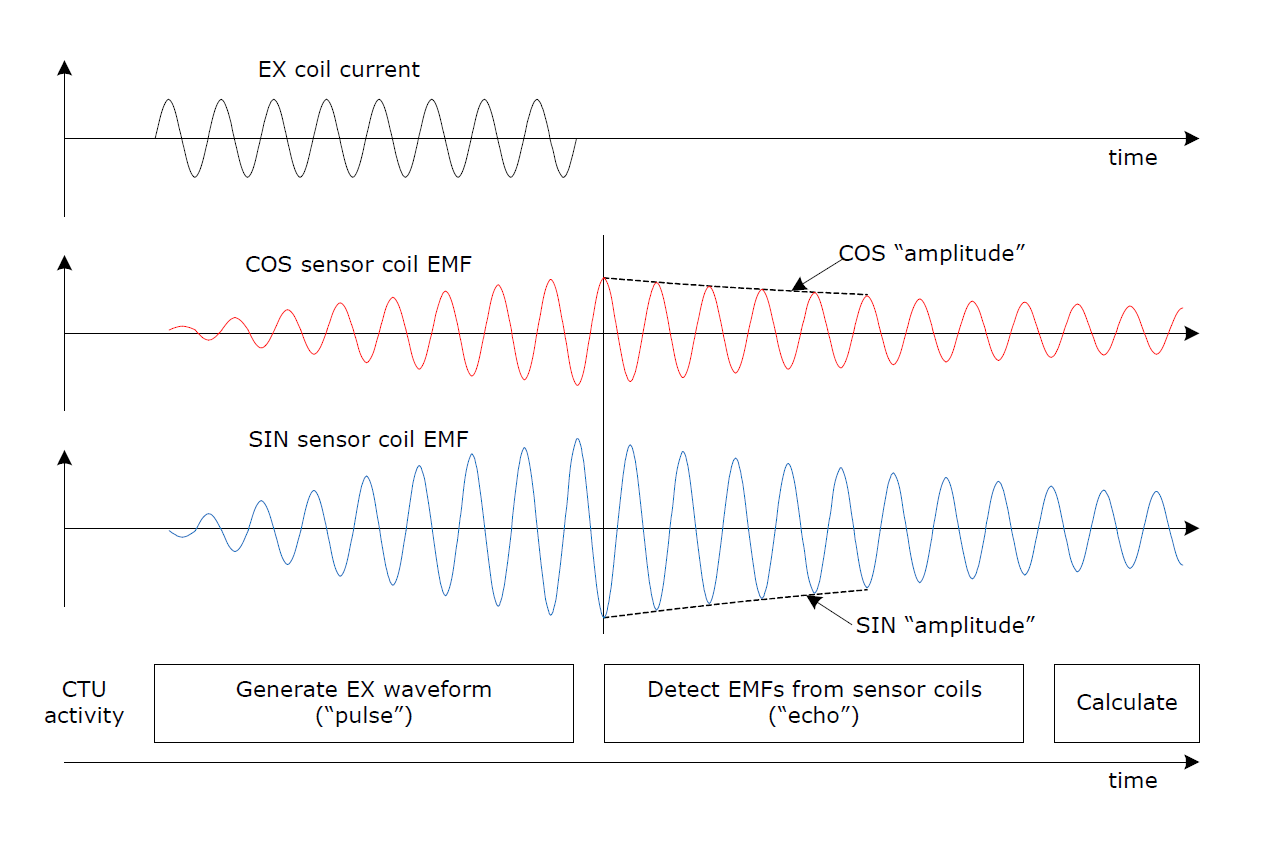

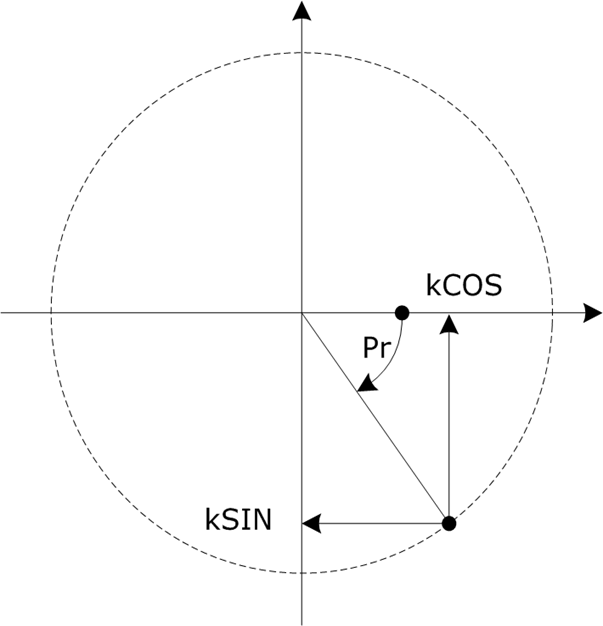

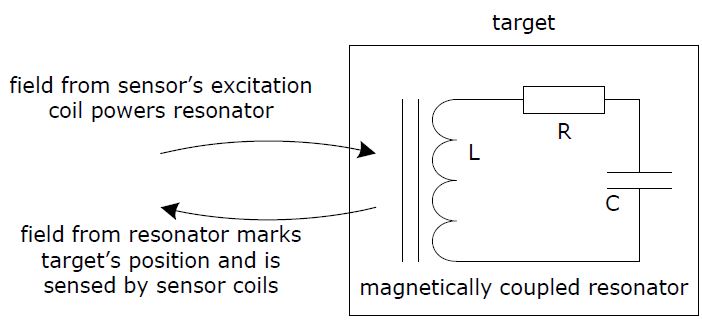

CambridgeIC develops integrated circuits for sensing the precise position of moving parts in machines. We specialise in resonant inductive position

sensing, and our team has been leading the development of this technology for over 18 years.

Our customers are designers of electromechanical products seeking an innovative edge. Resonant inductive technology helps simplify product manufacture.

Position sensors are built from conventional PCBs, so that they are accurate, robust and cheap to manufacture. However until CambridgeIC's foundation in 2007, the technology required

special design skills. Our mission is to make design-in straightforward, by providing customers with a single-chip solution and a set of standard designs and integration tools.

TURCK Exclusivity Notice for Industrially Housed Sensors

TURCK is a leading manufacturer in the field of industrial automation. We have partnered with TURCK to deliver a range of position sensing products for this market.

TURCK is CambridgeIC’s exclusive partner

“for fixed location industrial automation applications (i.e. factory or other production process), where the relevant sensor parts are industrially housed (i.e. within a separate unit and thereby protected from damage during installation and use), and then physically incorporated into the production line”

Business Model

Highlights |

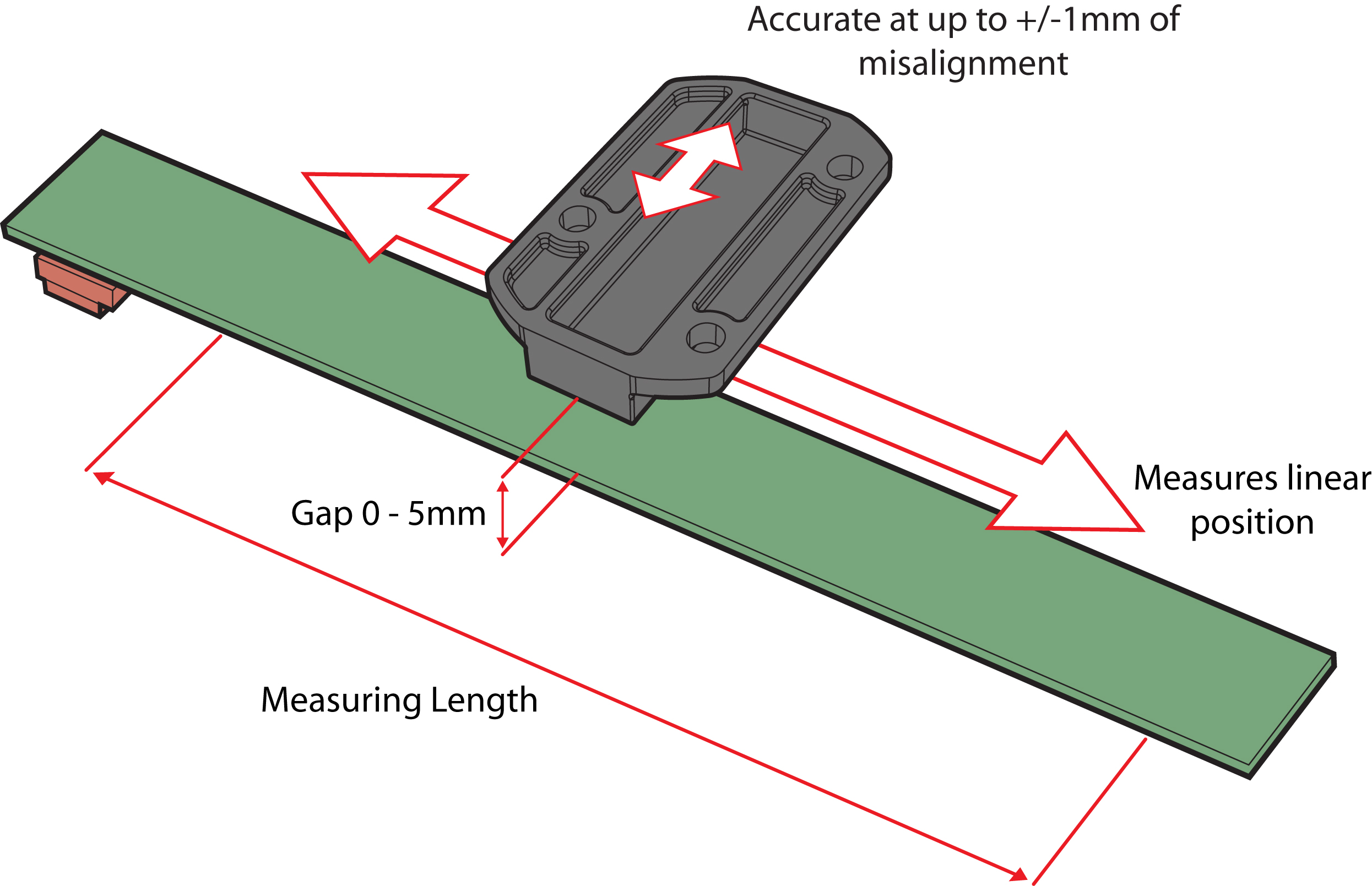

- absolute position sensing - low cost - non contact - large gap possible - tolerant of misalignment - insensitive against dirt, dust, oli, salt water, metallic swarf, cleaning fluids - multi axis - integrate sensors and electronics - stability from PCB technology - precision from CTU Chip - high resolution (10..16 bit) - high Q resonator for high signal level |

| Pictures | Description | Links | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

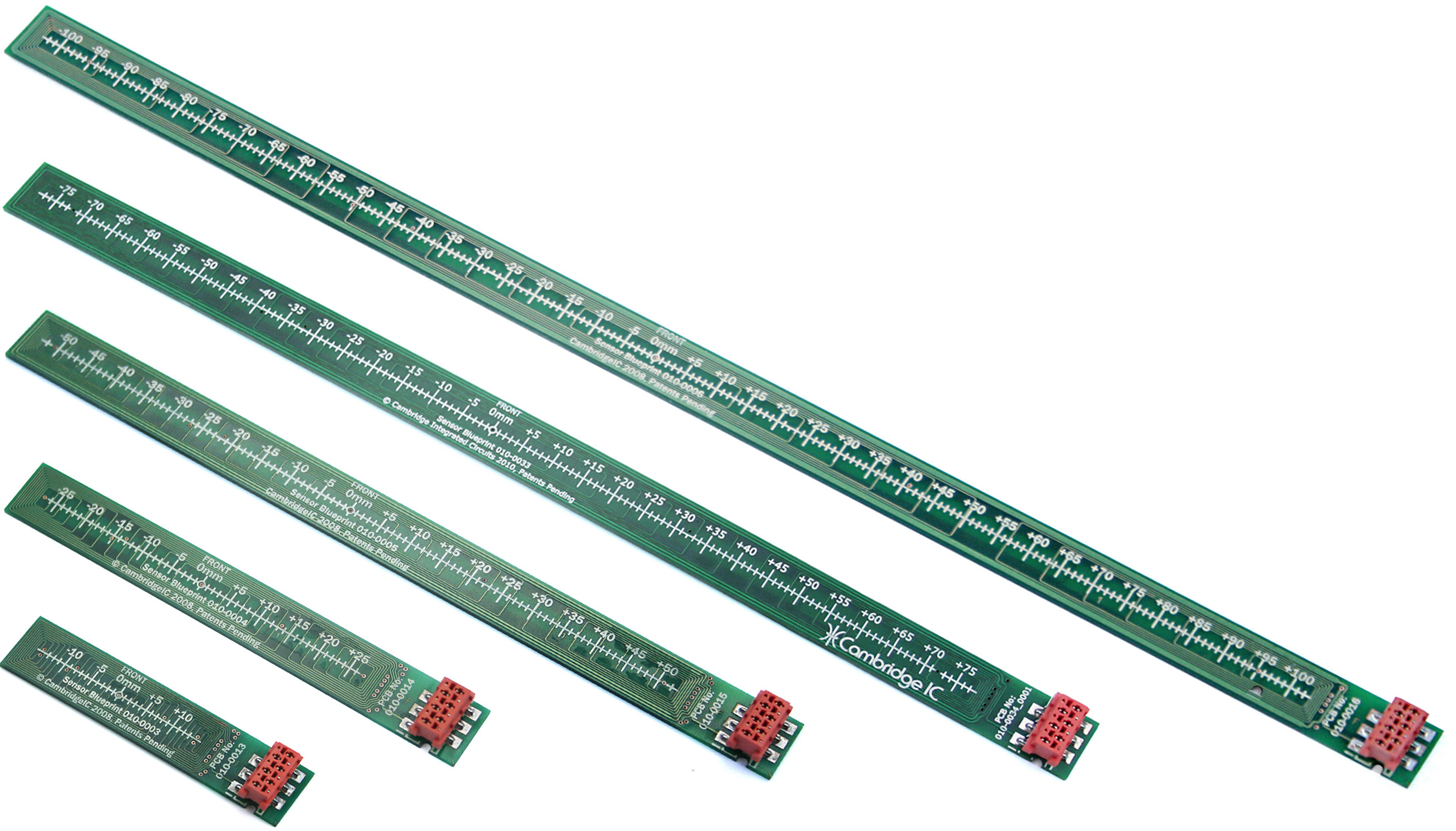

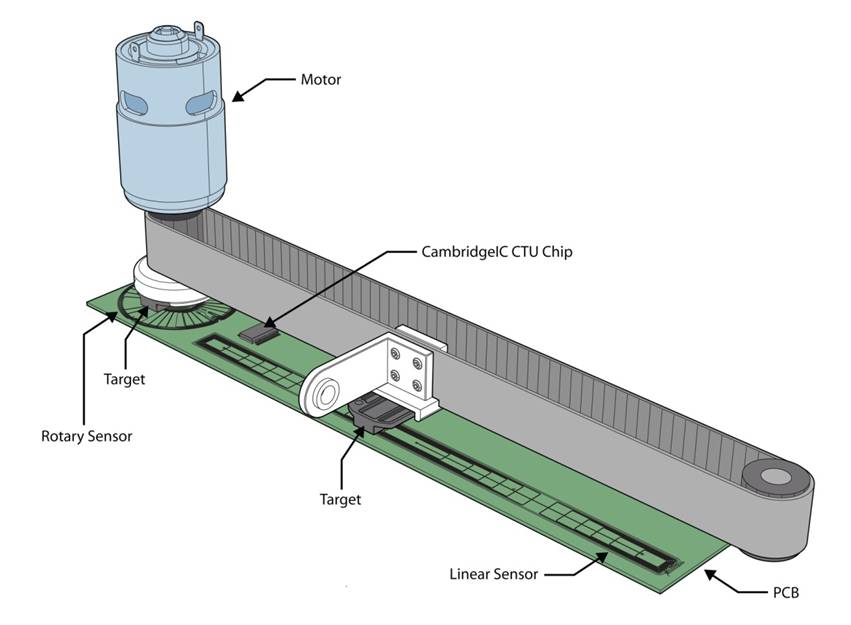

Type 1 Linear Sensors |

Single Channel Sensor (9-11 bit Noise Free Resolution) | |||||||||||||||||||||||||||||||

|

25mm Linear Sensor (013-007) 50mm Linear Sensor (013-008) 100mm Linear Sensor (013-009) 150mm Linear Sensor (013-013) 200mm Linear Sensor (013-010) 200mm Linear Sensor (013-019) To be used with the Standard Target (013-1005) or E-Core Target (013-1020) |

Datasheet |

||||||||||||||||||||||||||||||

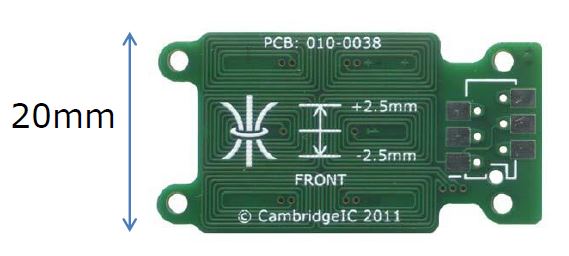

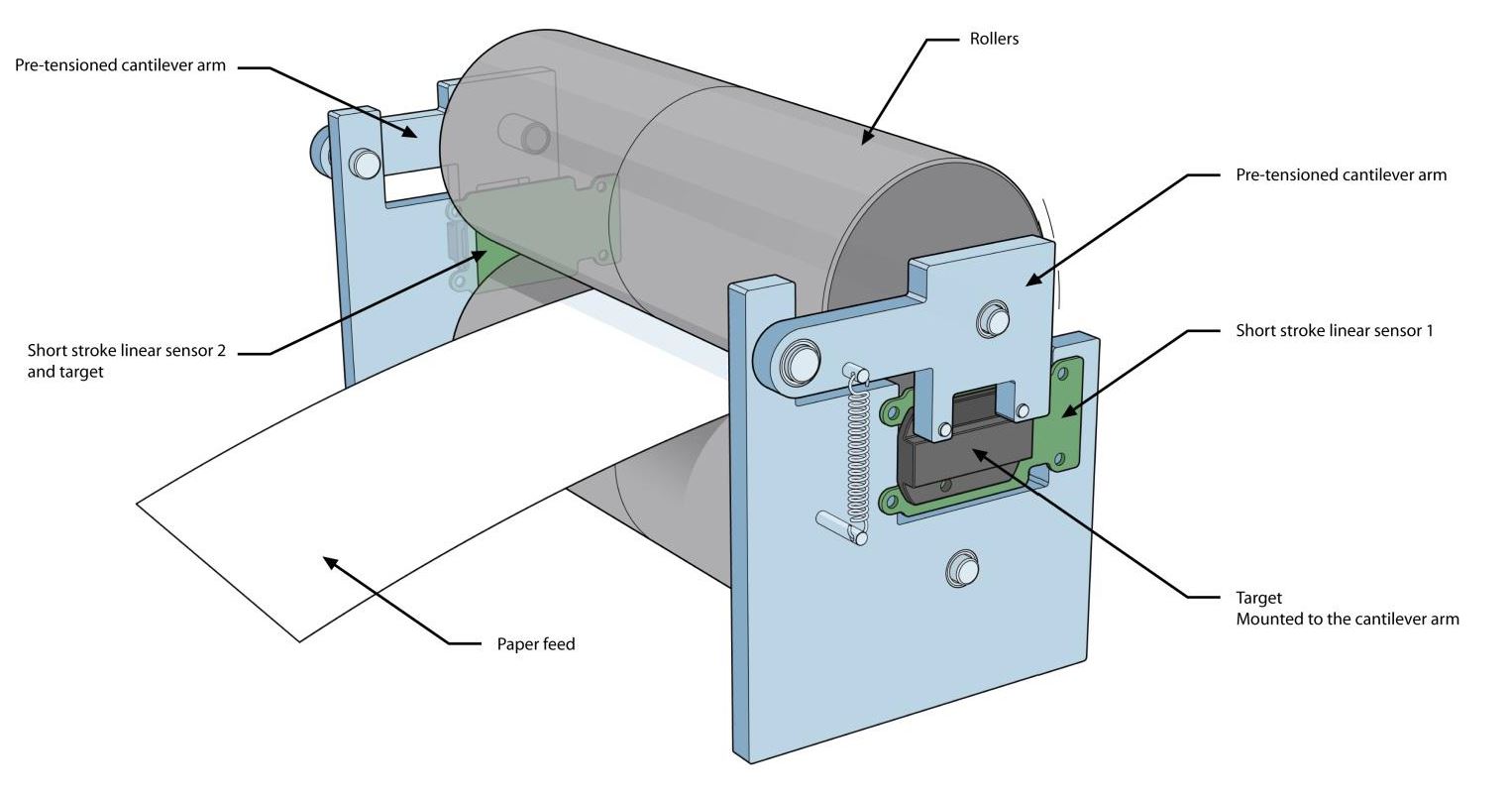

Type 4 Linear Sensors |

Single Channel Sensors(9-11 bit Noise Free Resoluion) | |||||||||||||||||||||||||||||||

|

To be used with the Standard Target (013-1005) 5mm Linear Short Stroke Sensor (013-0016) Application example: Paper thickness measurement |

|||||||||||||||||||||||||||||||

Type 2 & Type 6 Narrow Linear Sensors |

Dual Channel Sensors (up to 16 bit Noise Free Resolution) | |||||||||||||||||||||||||||||||

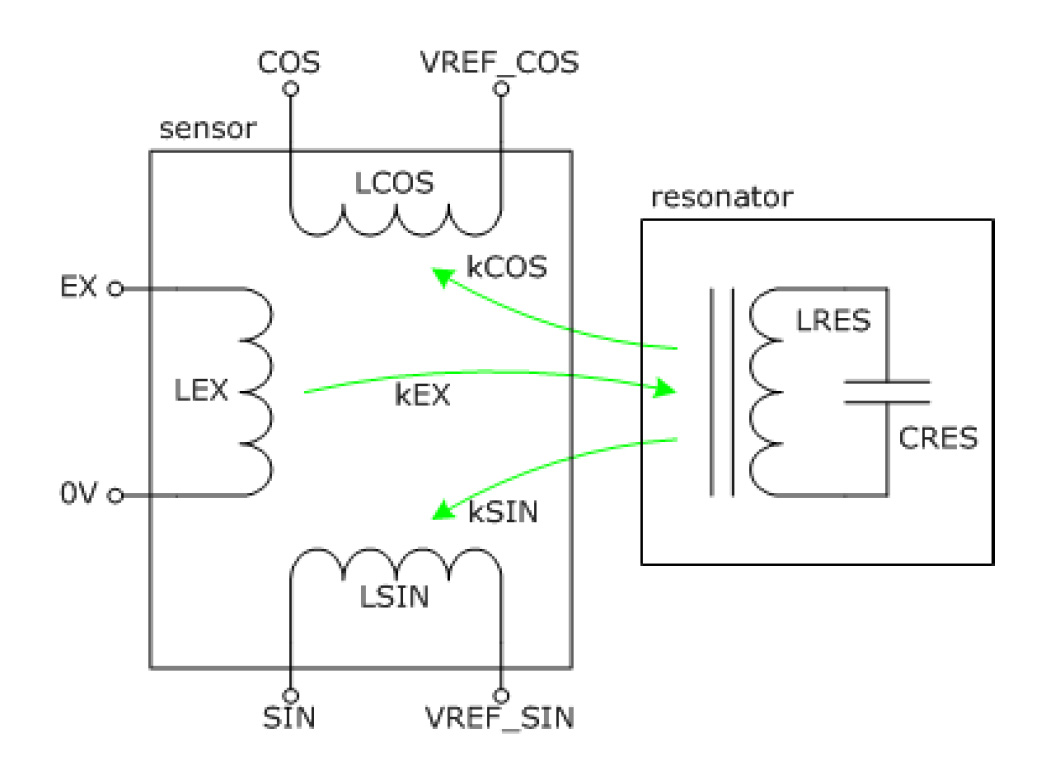

| Type 2 and Type 6 sensors offer performance improvements over Type 1 sensors. They do this with an additional "fine" set of sensor

coils. This fine track delivers high precision and accuracy, while a coarse track delivers an absolute output. The CTU chip connected to

the sensor combines the outputs of both tracks so that the position it reports to the host is always absolute, precise and accurate. To be used with the E-Core Target (013-1020) A single CAM204 CTU chip can operate up to two Type 6 sensors, including a mix of linear and rotary. The CAM204 can operate a single Type 2 sensor. Type 2 sensors offer greater measuring range than Type 6. Performance Gap 0,5mm to 2mm / Y Misalignment up to 0,5mm

|

75mm Type 6.4 205mm Type 6.8 350mm Type 2.12 500mm Type 2.12 |

|||||||||||||||||||||||||||||||

Type 2 wide Linear Sensors |

Dual Channel Sensors | |||||||||||||||||||||||||||||||

| This range of sensors offers precision and robustness with measuring ranges up to 1m. A sensor PCB width of 25.4mm allows the sensor to be

built on only 2 PCB layers which helps to reduce cost where space is available. They are used in TURCK's Li Series of industrially housed position sensors. Please contact CambridgeIC for the status of development kits and samples. |

| Part number | Description |

|---|---|

| 013-0057 | 78mm Axial Sensor Assembly |

| Part number | Description |

|---|---|

| 013-6001 | 300mm 6-way Sensor Connecting Cable |

| 013-1033 | L20 Red Target Sample |

| 010-0145 | Sensor Blueprint |

| Type 1 | Type 6 |

|---|---|

|

|

| Picture | Description | Datasheet |

|---|---|---|

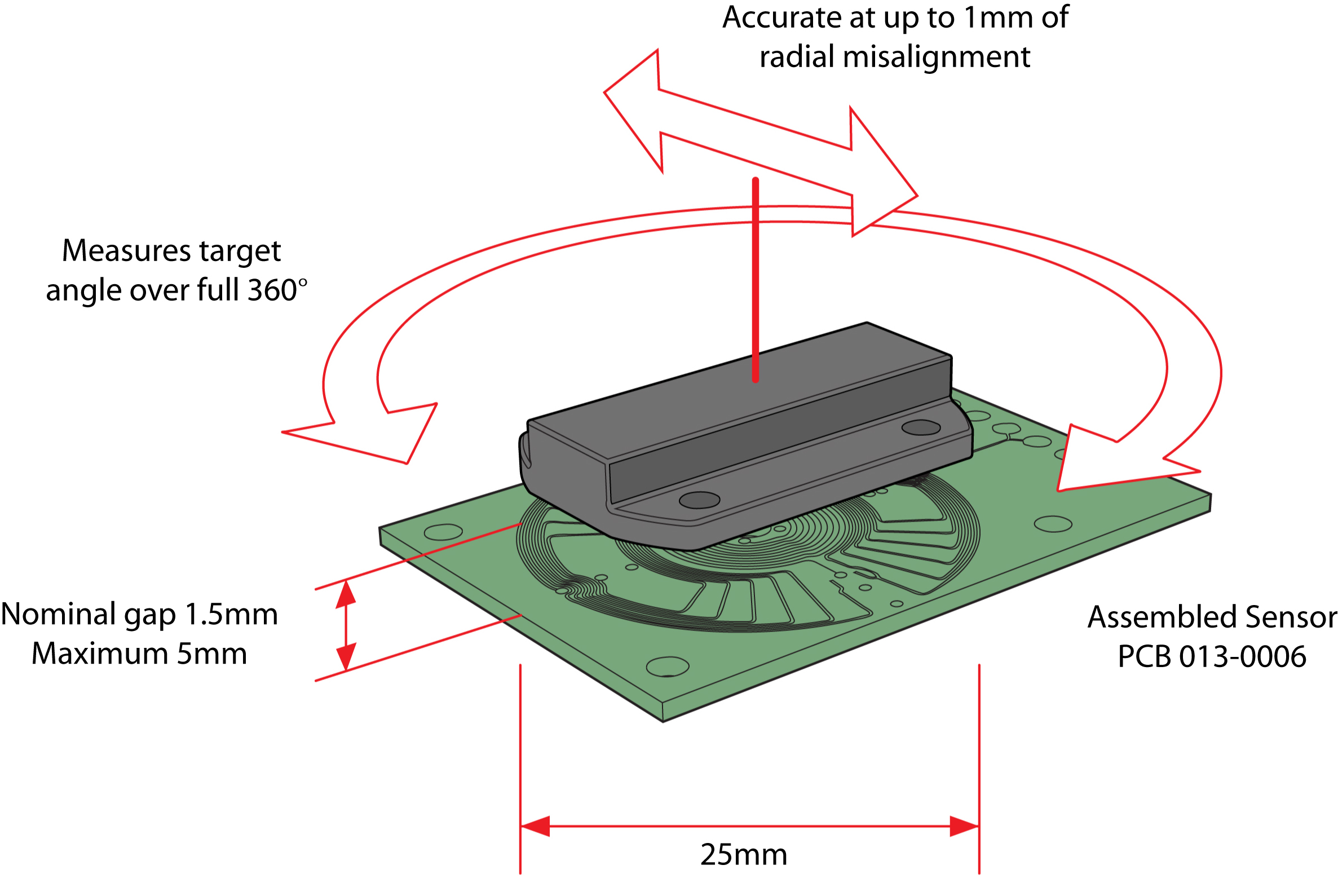

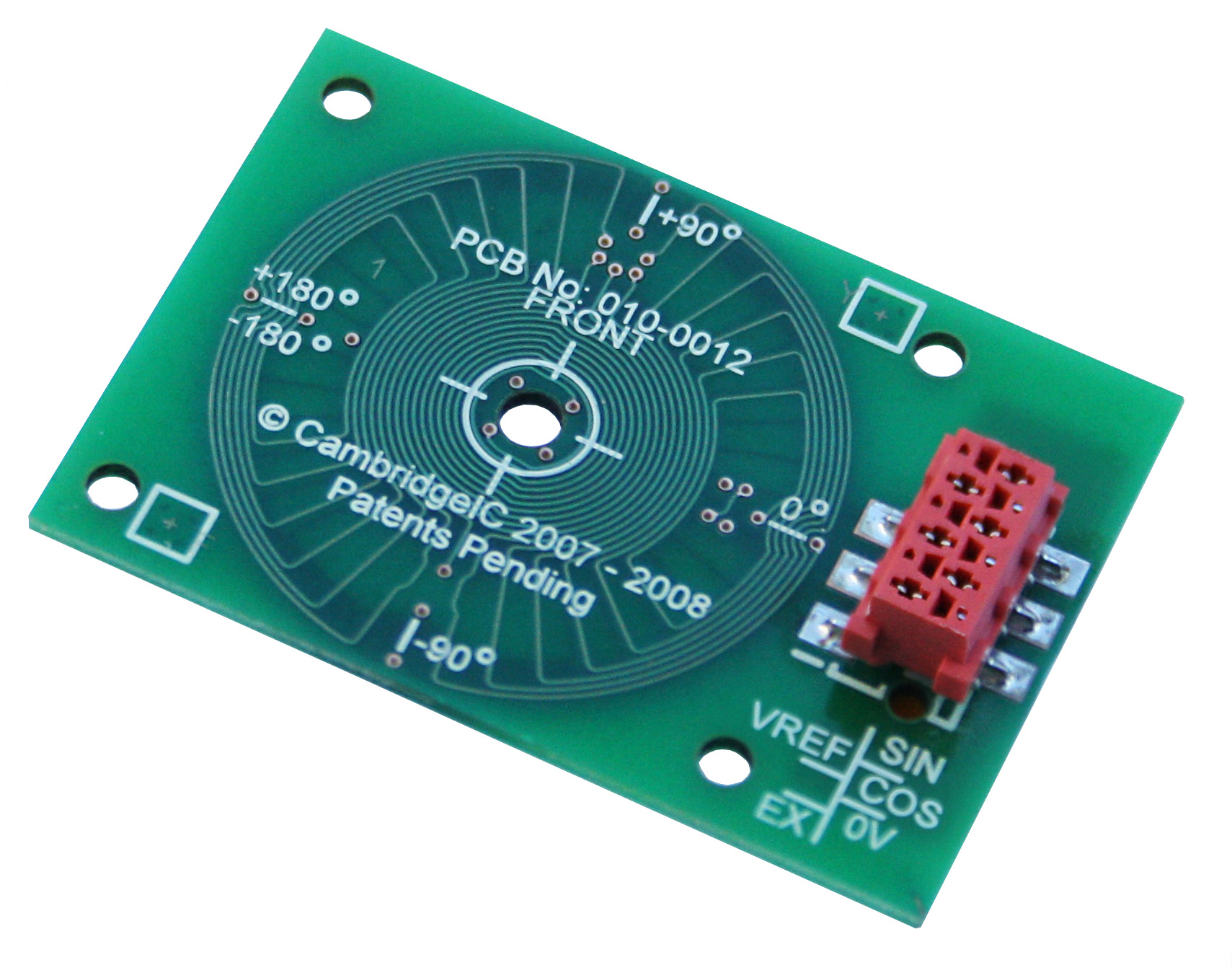

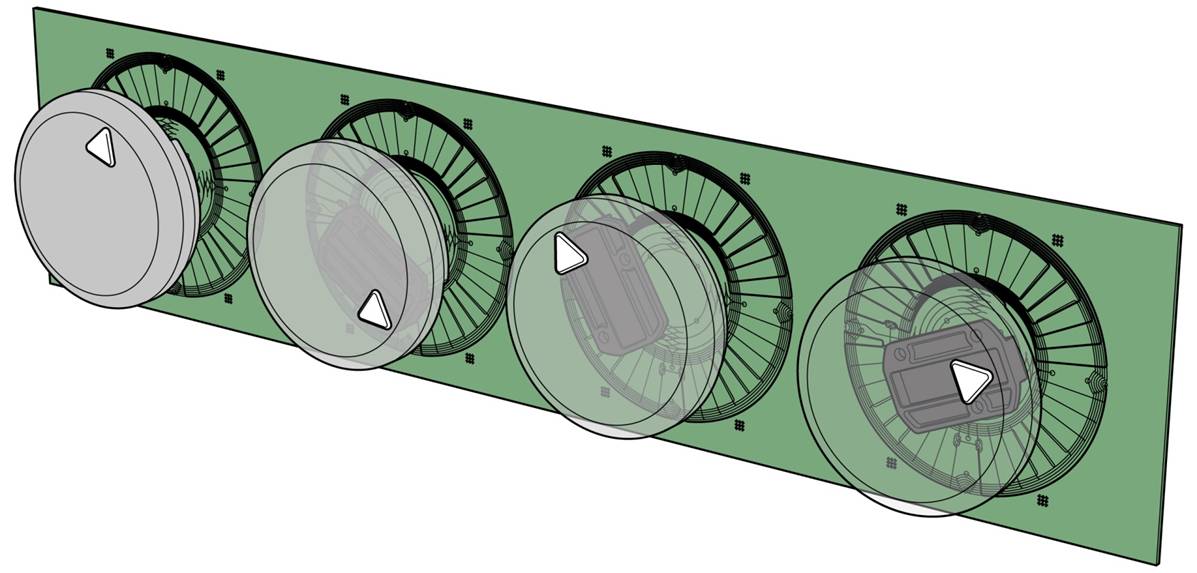

Type 1 Rotary Sensors[25mm] |

||

|

Single Channel Sensor (9–11 bit Noise Free Resolution) To be used with the Standard Target(013-1005) |

|

Type 1 Rotary Sensors[36mm] |

||

|

Single Channel Sensor (9–11 bit Noise Free Resolution) To be used with the Standard Target (013-1005) |

|

Type 1 Rotary Sensors[50mm] |

||

|

Single Channel Sensor (9–11 bit Noise Free Resolution) To be used with the Standard Target(013-1005) |

|

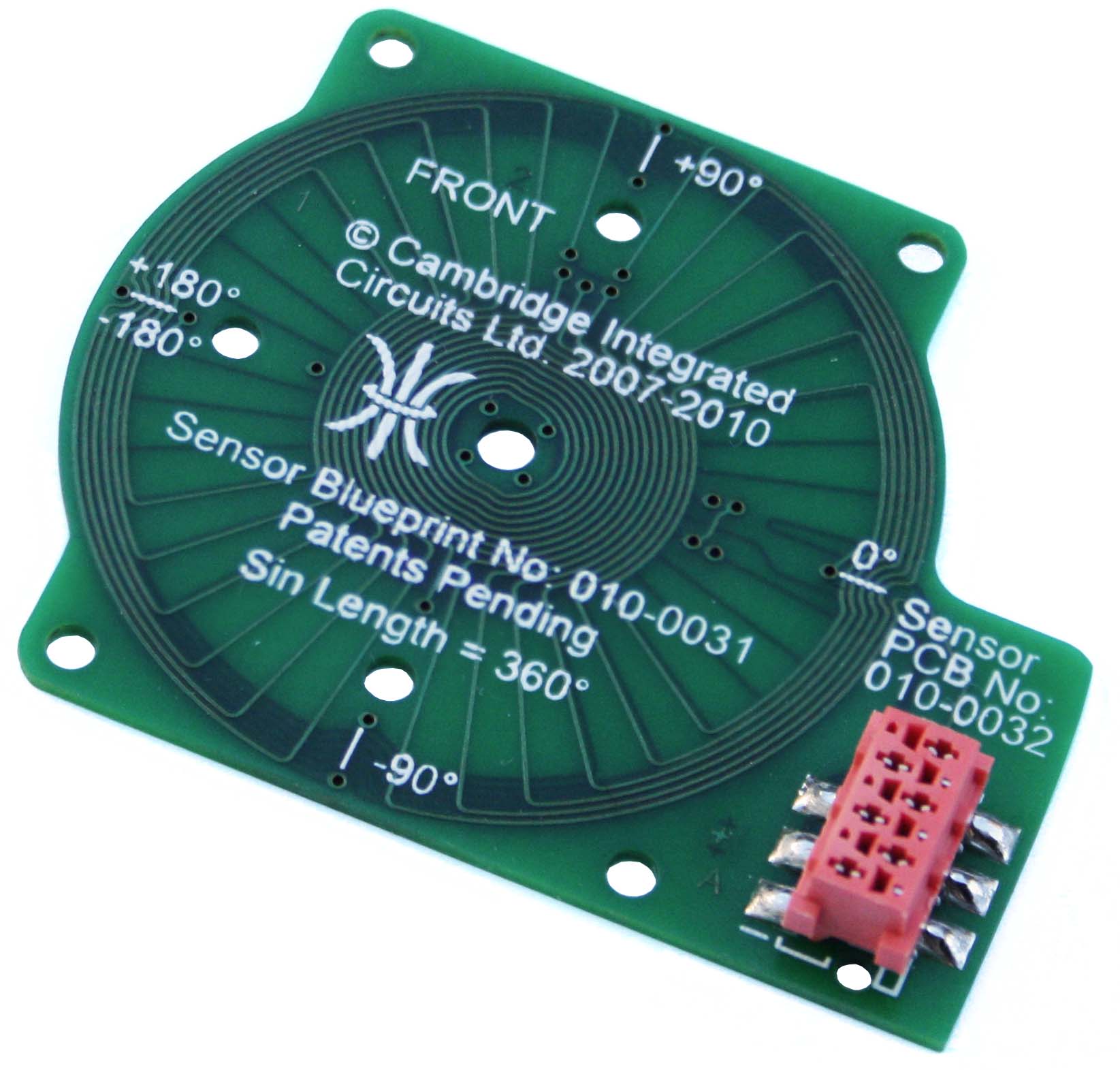

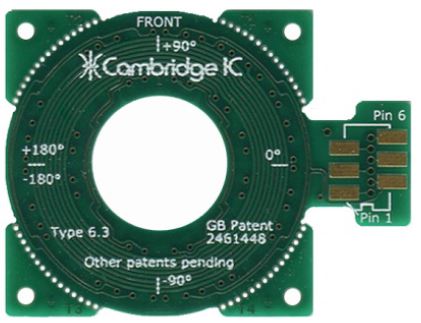

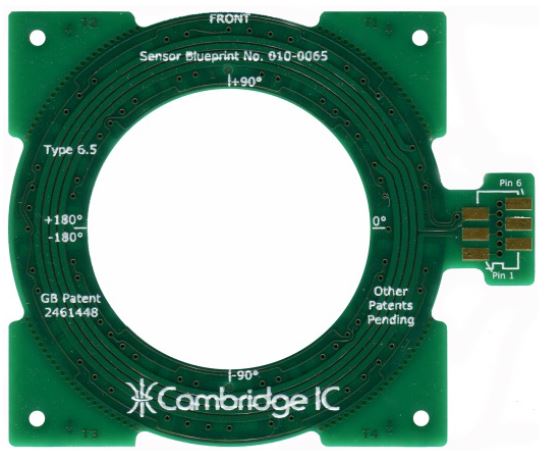

Type 6 Precision Through Hole Rotary Sensors[35mm] |

||

|

Dual Channel Linear Sensors (up to 16 bit Noise Free Resolution) To be used with a C-Target or board with Transponder-Coil |

Link to Demokit: |

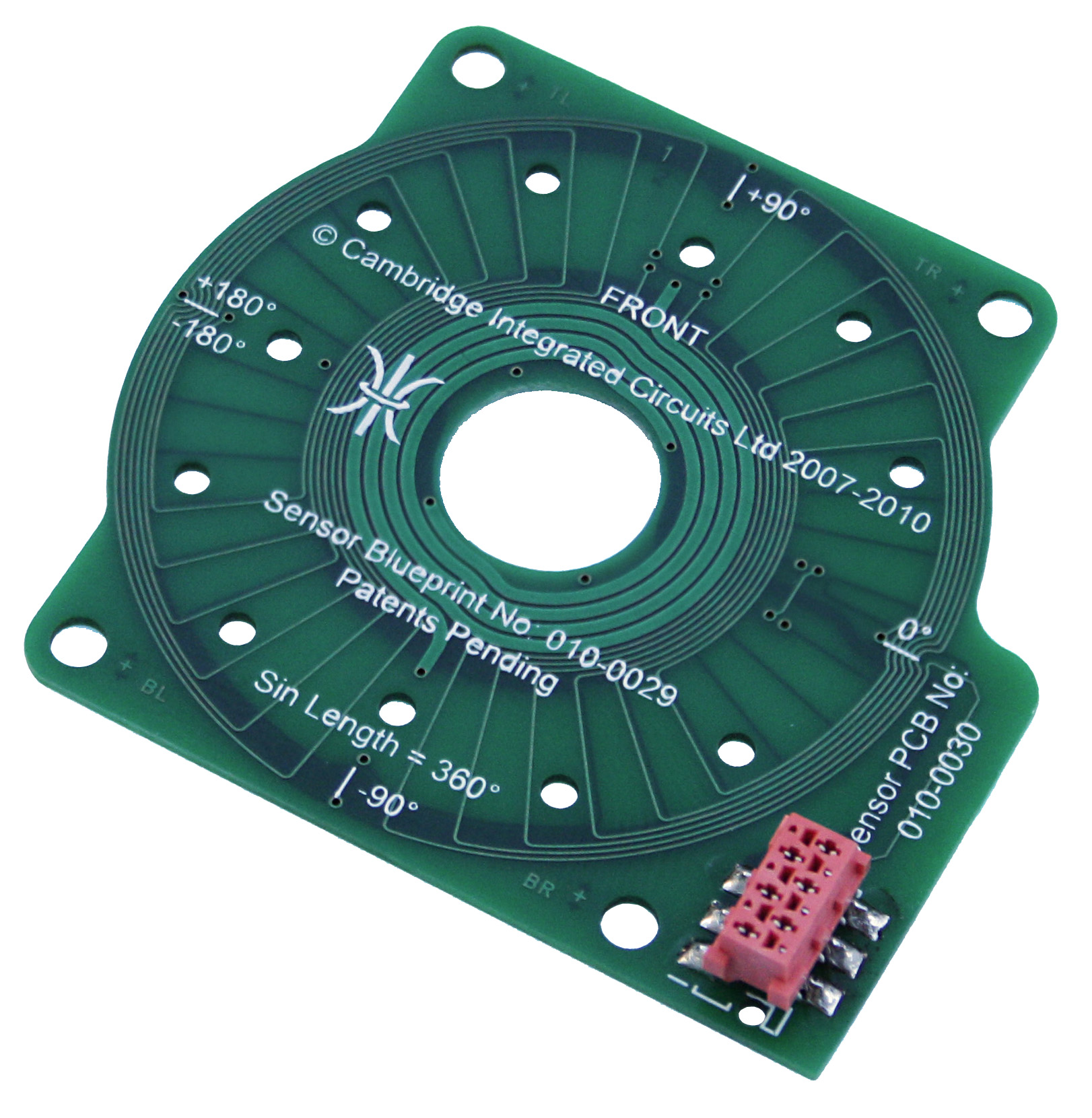

Type 6 Precision Through Hole Rotary Sensors[55mm] |

||

|

Dual Channel Linear Sensors (up to 16 bit Noise Free Resolution) To be used with a C-Target or board with Transponder-Coil |

Link to Demokit: |

| Part number | Description |

|---|---|

| 013-0044 | R25mm 100° Arc Sensor Assembly |

| 013-0045 | R30mm 100° Arc Sensor Assembly |

| 013-0046 | R36mm 100° Arc Sensor Assembly |

| 013-0047 | R48mm 100° Arc Sensor Assembly |

| 013-0048 | R68mm 100° Arc Sensor Assembly |

| 013-0049 | R100mm 100° Arc Sensor Assembly |

| Part number | Description |

|---|---|

| 013-6001 | 300mm 6-way Sensor Connecting Cable |

| 013-1005 | Standard Target |

| Picture |

|---|

Industrially housed sensors from TURCK |

|

Embedded actuator feedback |

|

Dial reading and control panels |

|

Thickness measurements |

|

ATM Cash Dispenser |

|

Pan/Tilt CCTV Camera |

|